3-D Scanning & Printing

What is 3-D Scanning & Printing?

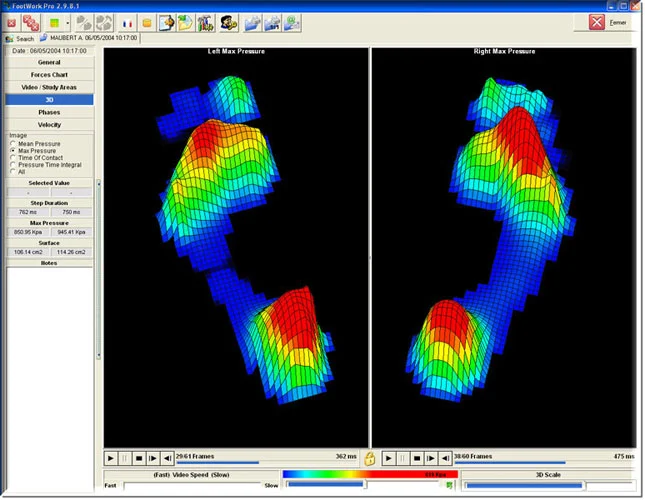

3D scanning offers unparalleled accuracy in capturing the intricate details of the foot and ankle. The digital models produced can be accurate to within a fraction of a millimeter, ensuring that the orthotic devices manufactured are highly precise and effective. This high level of accuracy leads to better fitting orthotics, which can significantly improve patient outcomes by providing optimal support and comfort.

Below are the proven benefits of 3D Scanning and how it might be suitable for you:

Precision and Accuracy

- Explanation: Captures exact dimensions and contours of the foot and ankle.

- Benefit: Ensures a perfect fit, enhancing comfort and effectiveness of orthotic devices.

Customisation

- Explanation: Creates bespoke orthotics tailored to individual needs.

- Benefit: Addresses specific medical conditions and personal requirements more effectively.

Efficiency

- Explanation: Reduces the time required for measuring and molding.

- Benefit: Speeds up the production process, resulting in faster delivery of orthotic devices.

Consistency

- Explanation: Provides uniform and repeatable results.

- Benefit: Ensures reliable quality across multiple devices.

Non-Invasive Process

- Explanation: Eliminates the need for plaster casting.

- Benefit: Enhances patient comfort and convenience during the fitting process.

Data Storage and Analysis

- Explanation: Stores digital scans for future reference and comparison.

- Benefit: Facilitates ongoing patient care and monitoring of changes over time.

3-D Printing

We regularly use 3D printing in our clinical practice and below are some of the advantages of employing this technology:

- Customisation: 3D printing allows for the creation of highly customised orthotic devices tailored to the individual's unique anatomy and needs. This level of customisation ensures a better fit and improved functionality compared to traditional mass-produced orthoses.

- Precision & Accuracy: With 3D printing technology, orthotic devices can be designed and produced with exceptional precision and accuracy. This helps in creating orthoses that provide optimal support and alignment, leading to improved patient outcomes.

- Complex Designs: 3D printing enables the fabrication of orthotic devices with intricate and complex designs that would be difficult or impossible to achieve using traditional manufacturing methods. This allows orthotists to design innovative solutions for a wide range of biomechanical issues.

- Reduced Lead Times: Traditional orthotic manufacturing processes often involve lengthy lead times due to the need for manual labour and multiple steps in the production process. 3D printing streamlines the manufacturing process, resulting in shorter lead times and faster delivery of orthotic devices to patients.

- Cost-Effectiveness: 3D printing allows for on-demand production, minimising waste and reducing the need for inventory storage.

- Sustainable Manufacturing: 3D printing minimises material waste and energy consumption compared to traditional manufacturing methods, contributing to a more sustainable and environmentally friendly approach to orthotic care.